|

HAWKER智能充电站 HAWKER CHARGER 霍克AGV智能充电桩

Product Features

This product is designed for automatic guided / pure electric passenger / electric forklift applications. Products from the basic power module N + 1 parallel combination, the maximum to meet the 24V120A power applications. The machine adopts the controller specially developed for AGV car application demand, realize the function of logic control, system protection, parameter setting, charger management, upper communication and so on, and adopts 7-inch full color touch screen to realize human-computer interaction.

The system has the following features:

●DC output 24V60A and 48V50A modular power supply, support current expansion upgrade.

●hot-swap mode, N + 1 redundant structure protection

●ultra-high power density, compact size

●Standard efficiency up to 92%

●variety use mode (independent charge, interactive charge, maintenance charge)

●With industrial communication bus (CAN / MODBUS / PROFIBUS DP)

●High protection safety rating (IP54), designed for industrial applications

This product is designed for automatic guided vehicles / electric forklifts and other applications. Products from the basic power module N + 1 parallel combination, the maximum to meet the 24V240A / 48V200A power applications. The machine adopts the controller specially designed for the AGV trolley application for the automatic production line. It realizes the functions of logic control, system protection, parameter setting, charger management, upper communication and so on, and adopts 7-inch full color touch screen to realize human-computer interaction.

The system has the following features:

●Ultra-high power, 240A @ 24V / 200A @ 48V

●hot-swap mode, N + 1 redundant structure protection

●ultra-high power density, compact size

●support current expansion upgrade

●Standard efficiency up to 92%

●Variety use mode (fast charge, interactive charge, balanced charge, maintenance charge)

●provide IO port for system interlock protection

●With industrial communication bus (CAN / MODBUS / PROFIBUS DP)

●High protection safety rating (IP54), designed for industrial applications

Product specifications

|

Voltage level |

24Vsystem |

48Vsystem |

|||||

|

model |

LPC120-24 |

LPC180-24 |

LPC240-24 |

LPC100-48 |

LPC150-48 |

LPC200-48 |

|

|

power |

3600W |

5400W |

7200W |

6000W |

9000W |

12000W |

|

|

recharging current |

5~120A |

5~180A |

5~240A |

5~100A |

5~150A |

5~200A |

|

|

Input voltage |

220VAC±10%,50/60Hz(Optional 380VAC±10%) |

||||||

|

Power factor |

≥0.99@220Vac/50A, ≥0.98@220Vac/25A(Single module) |

||||||

|

Dynamic adjustment rate |

±5.0% for 10-90% or 90-10% Load change,Adjust the time < 200us |

||||||

|

Load Regulation |

±0.5% from 10% to 100% load |

||||||

|

Charging voltage |

16~30VDC |

43~58VDC |

|||||

|

Steady flow accuracy |

≦±0.5% |

||||||

|

Noise voltage |

< 200 mV Peak peak, 30 MHz bandwidth, < 2 mV rms Telephone weight |

||||||

|

Regulation accuracy |

≦±0.5% |

||||||

|

Time accuracy |

≦±10S/24h |

||||||

|

Charging parameter settings |

Voltage |

0.01V |

|||||

|

Current |

0.1A |

||||||

|

time |

1S |

||||||

|

Dimensions |

According to power |

||||||

|

weight |

According to power |

||||||

|

Operating temperature |

0℃~45℃ |

||||||

|

Storage temperatur |

-10℃~40℃ |

||||||

|

Working humidity |

Relative humidity 10%~80%,No condensation |

||||||

|

protection |

Overcurrent, overvoltage, overtemperature, reverse, missing, short circuit, cut off |

||||||

|

communication |

CAN/MODBUS/PROFIBUS DPOptional |

||||||

|

InteractionDIO |

Dry contactDIO, Battery contact informs, standby, charging, charging is complete, faulty |

||||||

|

safety standard |

IEC 60950-1 |

||||||

|

Electromagnetic compatibility standards |

EN 61000-6 |

||||||

|

environment |

ETSI EN 300 019-2 RoHS compliant |

||||||

|

Insulation and pressure |

3.0 KVAC –Input pair output 1.5 KVAC –Input to ground 0.5 KVDC –Output to ground |

||||||

|

Average trouble-free working hours |

5Million hours |

||||||

|

noise |

50DB |

||||||

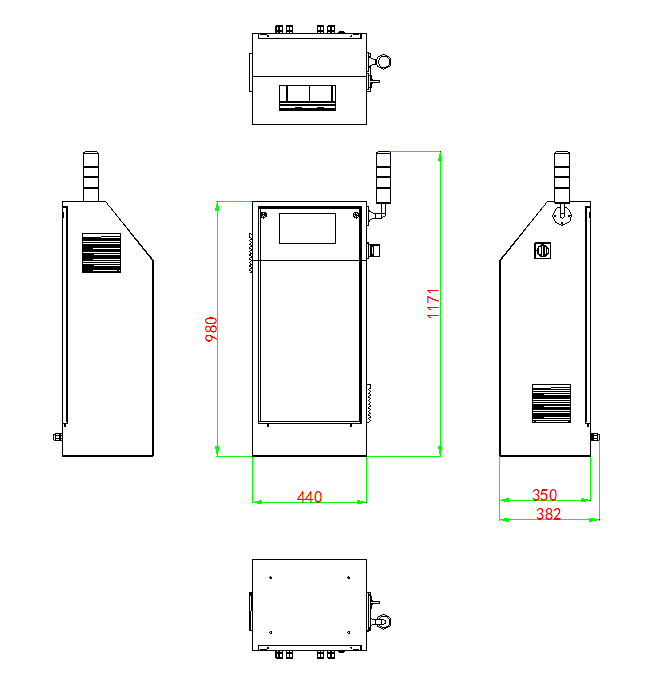

LPC120-24 charging station dimensions:

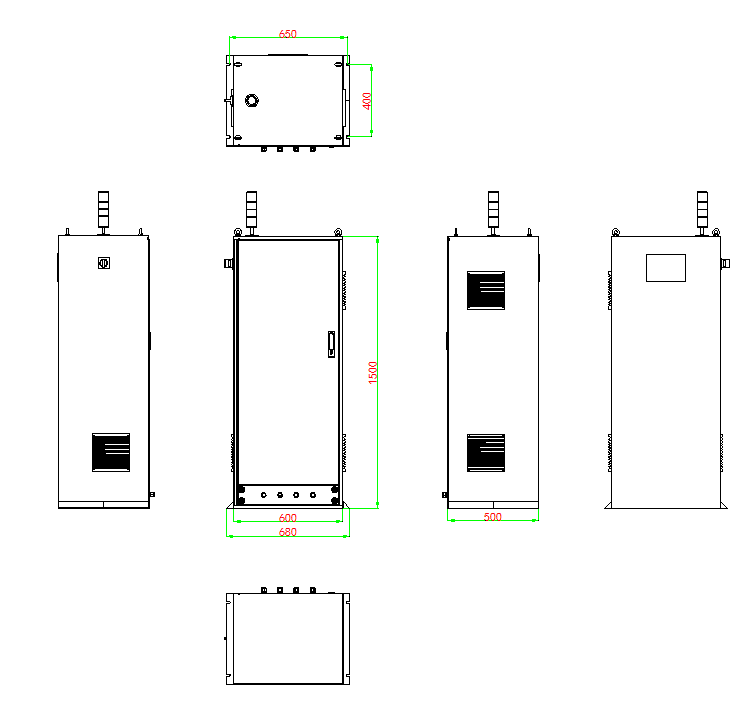

LPC120-24 above specifications charging station Dimensions:

The charging station uses floor-mounted foot installation mode.